Grantee Research Project Results

2010 Progress Report: Bioavailability of Metallic Nanoparticles and Heavy Metals in Landfills

EPA Grant Number: R833893Title: Bioavailability of Metallic Nanoparticles and Heavy Metals in Landfills

Investigators: Hu, Zhiqiang , Wall, Judy D. , Elias, Dwayne A.

Institution: University of Missouri - Columbia

EPA Project Officer: Aja, Hayley

Project Period: April 1, 2009 through March 31, 2012

Project Period Covered by this Report: April 1, 2010 through March 31,2011

Project Amount: $399,262

RFA: Exploratory Research: Nanotechnology Research Grants Investigating Fate, Transport, Transformation, and Exposure of Engineered Nanomaterials: A Joint Research Solicitation - EPA, NSF, & DOE (2007) RFA Text | Recipients Lists

Research Category: Nanotechnology , Safer Chemicals

Objective:

The objectives of this research are to determine bioavailability of nanoparticles and heavy metal species in bioreactor landfills as compared to traditional municipal solid waste landfills; and to elucidate the mechanisms governing bioavailability as well as the mode of antimicrobial action by nanoparticles. In order to accomplish these objectives, three hypotheses will be tested: 1) nanoparticles that can leach into the water from landfill runoff are bioavailable; 2) nanoparticles enhance heavy metal bioavailability and leachate toxicity; and 3) the bioavailability of nanoparticles and heavy metals is higher in bioreactor landfills than in traditional landfills.

Progress Summary:

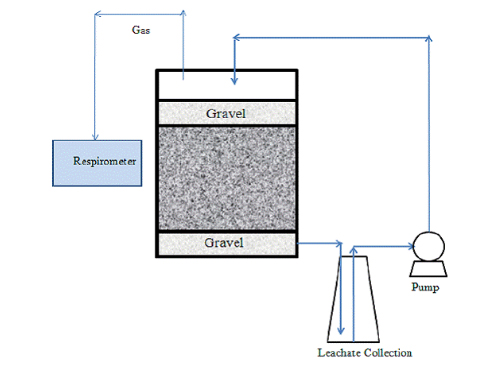

Figure 1. A schematic of lab-scale landfill reactor with leachate recirculation

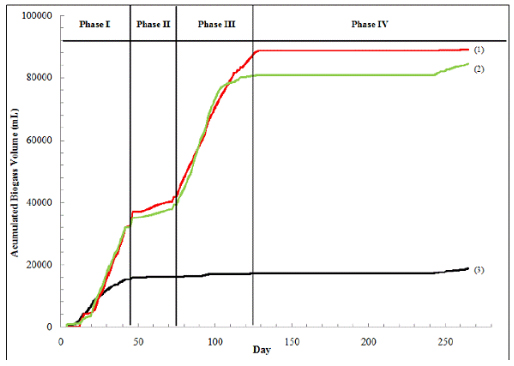

Figure 2. Cumulative biogas volume over time during the solids stabilization process in 9-L

bench-scale landfill bioreactors. Lines 1, 2, 3 represent cumulative gas volume in bioreactors

treated with no AgNPs (control), 1 mg AgNPs/kg, and 10mg AgNPs/kg respectively. Phase I,

Transition and Acid Formation: Phase II, Hydrogentrophic Methane Fermentation: Phse III,

Acetoclastic Methane Fermantation: Phase IV, Final Maturation.

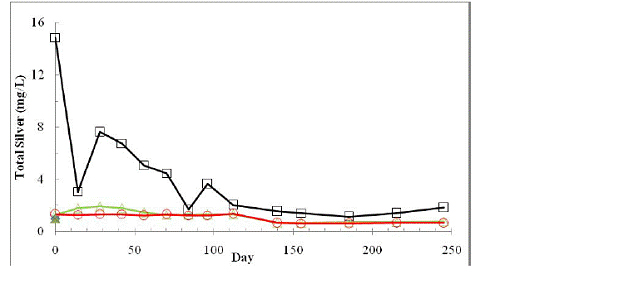

Figure 3. The change of the total silver concentrations in leachates of landfill bioreactors

treated with 0 AgNPs (control)(O), 1 mg AgNPs/kg (∆), and 10mg AgNPs/kg (□).

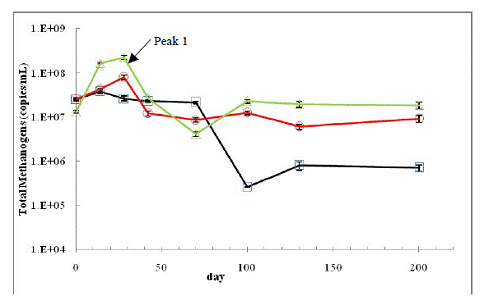

Figure 4. The change of the total methanogenic gene copies in the lechates of

bioreactors treated with 0 AgNPs (control), (Ο), 1mg AgNPs/kg (Δ), and 10 mg AgNPs/kg (□).

Erorr bars represent one standard deviation of triplicate samples.

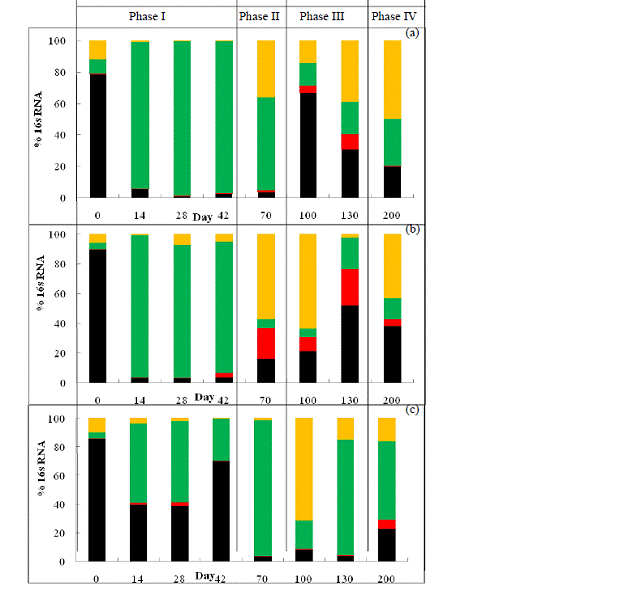

Figure 5. The changes of methanogenic composition (in relative 16s rRNA

gene copies) in landfill bioreactors treated with zero AgNPs (a), 1mg AgNPs/kg

(b), and 10 mg AgNPs/kg (c). Acetoclastic methanogens: Black, Methanosaeta;,

Red, Methanosarcina; Hydrogenotrophic methanogens: Green, Methanobacteriales;

Yellow, Methanomicrobiales.

Future Activities:

New batch experiments are run at mesophilic temperature conditions to evaluate the fate and toxicity of nanosilver in landfill systems and compare the difference of anaerobic digestion in landfills between the groups treated with nanosilver and its counterpart bulk silver.

Journal Articles on this Report : 1 Displayed | Download in RIS Format

| Other project views: | All 4 publications | 4 publications in selected types | All 4 journal articles |

|---|

| Type | Citation | ||

|---|---|---|---|

|

|

Yang Y, Chen Q, Wall JD, Hu ZQ. Potential nanosilver impact on anaerobic digestion at moderate silver concentrations. Water Research 2012;46(4):1176-1184. |

R833893 (2010) R833893 (Final) |

Exit Exit |

Supplemental Keywords:

bioavailability, cellular, heavy metals, analytical, absorption, adsorption, bioaccumulation, gene expression, growth, mechanisms, metabolism, toxins, nanotechnology, microbiology, biotechnologyProgress and Final Reports:

Original AbstractThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.