Grantee Research Project Results

2015 Progress Report: Integration of Filtration and Advanced Oxidation: Development of a Membrane Liquid-Phase Plasma Reactor

EPA Grant Number: R835332Title: Integration of Filtration and Advanced Oxidation: Development of a Membrane Liquid-Phase Plasma Reactor

Investigators: Bellona, Christopher , Holsen, Thomas M. , Mededovic Thagard, Selma , Dickenson, Eric

Current Investigators: Bellona, Christopher , Holsen, Thomas M. , Dickenson, Eric , Mededovic Thagard, Selma

Institution: Clarkson University , Southern Nevada Water Authority

EPA Project Officer: Packard, Benjamin H

Project Period: August 16, 2012 through August 15, 2016 (Extended to August 15, 2017)

Project Period Covered by this Report: August 16, 2014 through August 15,2015

Project Amount: $499,779

RFA: Research and Demonstration of Innovative Drinking Water Treatment Technologies in Small Systems (2011) RFA Text | Recipients Lists

Research Category: Drinking Water , Water

Objective:

Engineer, develop and demonstrate an integrated process comprised of membrane technology and electrical discharge plasma generated via a novel reticulated vitreous carbon (RVC) electrode material. The successful development of this process will result in a technology that is scalable, robust, requires minimal chemical input, has a small foot-print, and achieves a finished water quality better than treatment systems that require multiple technologies.

Progress Summary:

During the project period, the research team completed work to develop a demonstration-scale plasma reactor and continued to perform experiments with plasma reactors and various contaminants. Development of the demonstration-scale system required the evaluation of approximately 12 reactor designs with a suite of regulated and unregulated organic contaminants.

Phase I: Phase I of the current project was completed in year one and a summary of the work was provided in the first annual progress report.

Phase II: The objective of Phase II was to conduct bench-scale studies to optimize the plasma process for contaminant destruction, elucidate reaction mechanisms, and evaluate system water quality. Significant findings from the work performed during this phase were summarized in the 2014 Annual Report provided to the USEPA. However, the research group has continued to work on research related to this project phase and has summarized important results below.

Degradation of Perfluoroalkyl Acids: Perfluoroalkyl substances (PFASs) have received considerable recent attention due to their ubiquitous presence and recalcitrance in the environment and toxic properties. Manufacture and disposal of PFAS formulations and products, and use of aqueous fire fighting foams at various sites has resulted in PFAS contamination of groundwater and drinking water supplies. In particular, the presence of perfluoroalkyl acids (PFAAs, e.g., perfluorooctanoic acid (PFOA), perfluorooctanoic sulfonic acid (PFOS)) is problematic due to the difficulty of treatment for these compounds. Conventional and most advanced water treatment processes (including advanced oxidation) are not effective for the removal of PFAAs. As a result, researchers and practitioners have focused on the use of adsorbents such as activated carbon, and to a lesser extent, reverse osmosis for the treatment of PFAS contaminated water. However, relatively short breakthrough times have been reported for activated carbon, and both processes produce a residual requiring disposal.

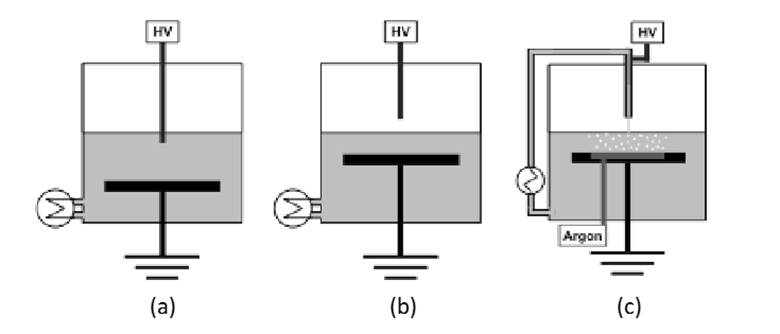

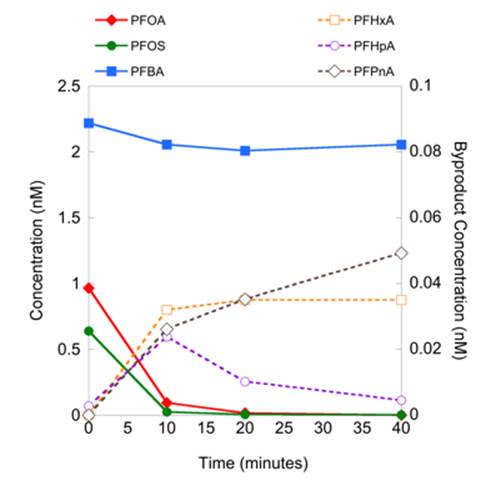

The research team performed experiments with a variety of regulated and unregulated contaminants at environmentally relevant concentrations (~500 ng/L) with the best performing plasma reactor identified to date (i.e., laminar jet with argon bubbling – Figure 1c.). Samples were collected for analysis at 20, 40, and 60 minutes of treatment and shipped to the Southern Nevada Water Authority for analysis. After 20 minutes of treatment time, PFOA and PFOS could not be detected in the effluent of the plasma reactor. Even more surprisingly, typical byproducts associated with PFAA oxidation were not formed in appreciable amounts. Further validation PFAA degradation results using the team’s plasma reactor are presented in Figure 2. Results indicate that surface-active perfluorinated compounds interact with the plasma channel and are reductively degraded through reactions with free electrons. Through these reactions, the team’s plasma reactor can achieve greater than 95 percent destruction of longer chain PFAAs in less than 10 minutes of reaction time. Through additional research, we believe we have developed the most efficient treatment technology for the removal of perfluorinated compounds to date.

Figure 1. Reactor diagrams: (a) point-plate with discharge in liquid, (b) point-plate with discharge in gas, and (c) laminar jet with argon bubbling

Figure 2. PFOA, PFOS and PFBA concentrations and byproduct (PFHxA, PFHpA, and PFPnA) formation during plasma treatment with the laminar jet reactor. Solid lines correspond to the concentration on the primary y-axis while dashed lines correspond to the concentration on the secondary y-axis.

Phase III: The objective of this project phase is to develop a scalable membrane/plasma system. The ceramic membrane system was constructed during the first year of the project and the team is finalizing the construction of the demonstration-scale plasma reactor. We originally proposed to develop a novel membrane housing that incorporated the plasma generation system. Through findings from completed work, however, we have modified the design so that the plasma reactor will be a standalone process.

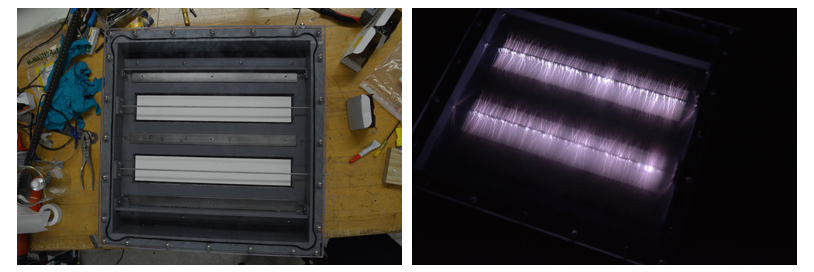

Demonstration-scale Plasma Reactor: Work commenced earlier this year on the development of a larger scale plasma reactor that would not require recirculation (i.e., flow through reactor). The reactor consists of two ceramic diffuser plates serving as the grounded electrode and two stainless steal rods serving as the high-voltage electrodes. The team is currently testing the reactor with surrogate organic contaminants and will refine the system design over the next month.

Figure 3. Constructed demonstration-scale plasma reactor (left) with plasma on (right).

Phase IV: The objective of this research phase is to demonstrate the developed technology. The research team is getting close to finalizing our proposed technology and is coordinating with the Southern Nevada Water Authority to test the system at one of their facilities early 2016.

Major Research Findings to Date:

- There are a number of factors that influence the effectiveness of plasma for the degradation of organic contaminants. By evaluating all of the factors that affect the kinetics of degradation, the research team has identified the main parameters that need to be optimized to improve the process.

- The major factors impacting the effectiveness of plasma in degrading organic contaminants include maximizing the contact between contaminants and plasma, utilizing the hydrogen peroxide produced by plasma, and adjusting the power supply parameters to increase plasma efficiency.

- Increasing the contact between plasma and contaminants was achieved by increasing the grounded electrode area, sparging the solution with argon, and passing the feed solution through the high voltage electrode.

- Producing plasma in the gas phase is much more effective than producing plasma in the liquid phase.

- Producing plasma with a multiple point electrode material is much more effective than with a single point high-voltage electrode.

- By optimizing the plasma reactor, contaminant degradation kinetics were increased by more than 20 times.

- Degradation experiments with a wide variety of organic contaminants demonstrated that plasma is an effective degradation process however, hydrophilic and non-surface active compounds were not always well removed. We theorize that compounds must interact with the plasma channel to be well degraded.

- The plasma process produces a significant amount of hydrogen peroxide. Fenton’s reaction can be initiated by adding ferrous iron or by using an iron-coated electrode, which significantly improves contaminant degradation for compounds that do not interact with the plasma channel.

- Plasma is very effective for the degradation of perfluorinated compounds particularly when using the team’s optimized reactor configuration. Results from various experiments indicate that the team’s optimized plasma reactor system is the most efficient treatment process for the destruction of perfluorinated compounds.

Progress: We have mostly finished Phase II (besides some perfluorinated chemical work that we are finalizing) and are now working on Phase III of the project. We are slightly behind on Phase IV as we are currently testing the demonstration-scale system that was fabricated at Clarkson. We initially proposed to demonstration test the system over a period of a year but feel that a shorter period of demonstration testing will not compromise the outcomes from this study. Therefore, the team believes that we are making good progress and generating interesting results.

Future Activities:

We are finalizing all experiments needed to publish two manuscripts on plasma treatment of perfluorinated compounds. The demonstration-scale reactor has been constructed and near-future activities planned are to test the system and make any changes necessary. Once work has been completed, the membrane-plasma system will be demonstration tested over a period of 4 to 6 months.

Journal Articles on this Report : 1 Displayed | Download in RIS Format

| Other project views: | All 22 publications | 6 publications in selected types | All 6 journal articles |

|---|

| Type | Citation | ||

|---|---|---|---|

|

|

Stratton GR, Bellona CL, Dai F, Holsen TM, Mededovic Thagard S. Plasma-based water treatment: conception and application of a new general principle for reactor design. Chemical Engineering Journal 2015;273:543-550. |

R835332 (2015) R835332 (2016) R835332 (Final) |

Exit Exit Exit |

Supplemental Keywords:

Drinking water, chemicals, engineering, innovative technology, membrane filtration, advanced oxidation, plasma reactor;Progress and Final Reports:

Original AbstractThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.