Grantee Research Project Results

Final Report: Characterization and Quantification of per- and polyfluoroalkyl substances in landfill gas and estimate of emissions from U.S. Landfills

EPA Grant Number: R839600Title: Characterization and Quantification of per- and polyfluoroalkyl substances in landfill gas and estimate of emissions from U.S. Landfills

Investigators: Barlaz, Morton A. , Field, Jennifer , Simonich, Staci

Institution: Oregon State University , North Carolina State University at Raleigh

EPA Project Officer: Hahn, Intaek

Project Period: September 1, 2019 through August 31, 2022 (Extended to August 31, 2024)

Project Amount: $900,000

RFA: Practical Methods to Analyze and Treat Emerging Contaminants (PFAS) in Solid Waste, Landfills, Wastewater/Leachates, Soils, and Groundwater to Protect Human Health and the Environment (2018) RFA Text | Recipients Lists

Research Category: Drinking Water , Water Quality , Human Health , Water , PFAS Treatment

Objective:

The overall research objective is to estimate the mass of per- and polyfluoroalkyl substances (PFAS) that are present in landfill gas (LFG) and the mass of PFAS released as fugitive emissions from U.S. landfills. Sub-objectives are to: (1) develop methods to sample and analyze LFG for targeted PFAS, (2) measure PFAS concentrations at a cross section of U.S. landfills in different climatic regions, (3) develop and implement a model to estimate PFAS production and emissions at the U.S. national scale, (4) evaluate the potential impact of soil attenuation on PFAS emissions and (5) measure gas-phase PFAS release from food packaging and municipal solid waste.

Summary/Accomplishments (Outputs/Outcomes):

Task 1: Develop methods to sample and analyze PFAS in Landfill Gas

A method was developed to sample and analyze volatile PFAS in LFG. The sampling method consists of a sampling port connected to the LFG header pipe or gas wellhead, followed by a glass fiber filter and a three-position solenoid valve to divert flow towards a manifold where three thermal desorption (TD) tubes are installed in parallel. A safe sampling volume of 350 mL volume of LFG, determined in optimization experiments, is obtained by passing a precise flow of 100 ± 0.5 mL/min to a sorbent tube, using a factory-calibrated mass flow controller (Alicat Scientific, Tucson, AZ). A GEM 5000 (LANDTEC, Dexter, MI) is also connected in-line to measure methane concentrations, followed by a connection to an explosion-proof vacuum pump (KNF, Germany) to overcome the vacuum pressure (-7 kPa to -2 kPa) of the gas collection system. Flexible tygon tubing was connected using stainless steel hose clamps, while rigid stainless-steel tubing was connected with compression fittings.

The analytical method utilized a sorbent tube-based sampling system, followed by TD, and analysis by gas chromatography mass spectrometry (GC-MS). The method was applied to landfill gas samples (Task 2) and samples from the reactor system (Task 5). Spike recovery of surrogates on TD tubes ranged from 77 to 98% at ~350 mL sample size. The field, trip and sampling blanks never showed quantifiable concentrations of any of the 25 target PFAS.

Task 2: Measure PFAS concentrations at a cross section of U.S. landfills in different climate regions

A total of 334 samples from 30 landfills were collected. Of the 30 landfills, 5 were in arid regions (0 – 50.8 cm precipitation/yr), 8 were in moderate regions (50.8 – 101.6 cm/yr) and 17 were in wet regions (> 101.6 cm/yr). The primary focus was to collect samples that represent PFAS concentrations in fugitive LFG emissions and concentrations as the gas would be treated in a control device (e.g., flare, internal combustion engine). Thus, samples were collected upstream of the landfill’s condensate knockout system to represent fugitive emissions and downstream to represent gas as it would be combusted. In addition, at some landfills, LFG from individual gas wells was sampled in an effort to analyze PFAS concentrations as a function of waste age. Such samples were collected when there was information on the age of the waste impacted by an individual gas well. Of course, the waste age was likely a range of several years.

The PFAS concentrations upstream and downstream of condensate knockout were statistically similar and thus combined to calculate a total summed PFAS concentration in LFG. PFAS concentrations in LFG sampled from landfills in arid and moderate regions were statistically similar but higher than concentrations in LFG from landfills in wet regions. PFAS concentrations in arid, moderate and wet regions were treated separately in Task 3 to estimate U.S. PFAS emissions from LFG. The median PFAS concentration in LFG in arid, moderate and wet regions was 6.87 x 107, 3.73 x 107 and 1.51 x 107 pg/m3, respectively.

Task 3

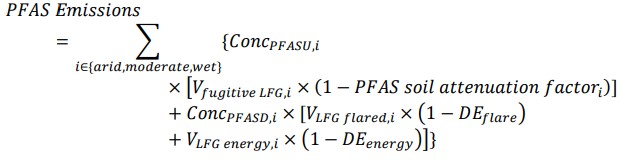

National PFAS emissions were calculated using equation ES-1. This equation was written in the most general form which allowed for different PFAS concentrations upstream and downstream of condensate knockout and varying PFAS concentrations by climate. Estimates of U.S. LFG emissions and utilization are given in the main body.

| (ES1) |

Where ConcPFASU.i and ConcPFASD.i are the summed PFAS concentration in LFG in each climate upstream and downstream of condensate knockout, respectively. Vfugitive LFG,i is the total volume of LFG that escapes through the soil cover. It was estimated based on the volume estimates of

CH4 generation [VCH4 generated, i] and recovery in a flare or engine [VCH4 flared, i, VCH4 for energy, i], assuming that LFG is 50% CH4 (eq. 2 in main body). [VCH4 generated, includes the gas generated from landfills with and without a GCS. While some CH4 is converted to CO2 in the soil, this does not change the volume of emitted gas. DEflare and DEenergy represent the PFAS destruction efficiency in a flare and internal combustion engine, respectively.

The application of equation ES-1, using the median PFAS concentrations for each climate, resulted in a point estimate of 685 kg summed PFAS/yr emitted to the environment. This estimate assumed no attenuation of PFAS in the fugitive emissions that pass through landfill cover soil, and 100% destruction of PFAS in flares and engines. The absence of soil attenuation s based on the limited results of Task 4. Several additional implementations of eq. ES-1 were conducted to evaluate the sensitivity of our estimate. Emissions range from 87 – 1630 kg/yr when the 25 and 75% quartile concentrations are used, and are 1020 kg/yr when the median PFAS concentration is used but only 50% PFAS destruction is assumed.

This is the first study to estimate the mass of PFAS release in the gas from U.S. landfills and is comparable to a previous estimate of leachate release of ~600 kg annually (Lang et al., 2017). Given the range of PFAS concentrations across landfills, emissions from an individual landfill will be site-specific in consideration of PFAS concentration, fugitive emissions and control device destruction efficiency. In the short-term, reductions in PFAS emissions will result from increased LFG collection, assuming some destruction in a landfill’s control device. Longerterm, efforts to reduce the mass of PFAS used on consumer products that are routinely disposed in landfills can be expected to reduce PFAS release from landfills.

Task 4: Assess the impact of soil on the attenuation of PFAS in LFG that is not collected

The objective of this task is to evaluate the potential for the attenuation or transformation of PFAS in landfill cover soils. LFG collection is imperfect and some gas escapes through the cover soil. We fabricated a static chamber for this task to measure the concentration signature of PFAS that has been released through a soil cover. We then compared this concentration signature with that of PFAS collected in LFG in the buried waste adjacent to and below the soil cover. PFAS signatures in the gas in the waste mass adjacent to the static chamber and in the gas that passed through the landfill cover soil were similar at two landfills. Thus there is no evidence of PFAS in attenuation in the landfill cover soils that were tested.

Task 5: Measure the release of volatile PFASs from residential MSW and food waste packaging during anaerobic decomposition

Forty-six packaging materials, including paper plates, microwaveable popcorn bags (MPBs), take-out food boxes, food wrappers, and various food containers were collected from local restaurants, online retailers, and grocery stores. Samples were first screened for total F by particle-induced gamma ray emission (PIGE) spectroscopy. Samples that contained >386,000 ng corrected total F/g by PIGE were then screened for methanol-extractable volatile PFAS. Based on the screening, 13 samples were classified as High F, including five paper-based food packaging and eight MPBs, and an additional 5 samples were classified as Low F. A laboratoryscale reactor system was designed and assembled to measure the release of volatile PFAS under conditions that represent the biological and chemical matrix of a landfill (Table ES-1).

Volatile PFAS release in the High and Low F reactors ranged from 20.4 – 799 and 0.09 – 0.62 ng PFAS/gm material, respectively, so there was a clear distinction in PFAS release among the high and low F materials. Among the High F materials, 6:2 FTOH accounted for 96.8 – 99.9% of the summed PFAS. 6:2 FTOH was landfills within a year of waste burial and fresh PFAS-containing waste is added over the life of the landfill. Nonetheless, the fact that PFAS have been measured in LFG indicates that release occurs over time.

This is the first report of the release of volatile PFAS associated with single-use packaging materials to the gas phase during anaerobic decomposition. The FTOHs were the dominant PFAS released from the high F materials tested in this study, which is consistent with observations of the PFAS composition of LFG (Task 2).

Table ES-1 Food packaging materials selected for study of PFAS release in landfill simulation reactors.

| Reactor Group | No. of reactors | Test material description |

|---|---|---|

| High F | 1 | popcorn bags 1-6 brands of microwavable popcorn bagsb |

| High F | 1 | popcorn bags 2-2 brands of microwavable popcorn bagsb |

| High F | 1 | compostable bowls (1 brand)* |

| High F | 1 | biodegradable boxes (1 brand)* |

| High F | 1 | bagasse (sugar cane residue) containers (1 brand) |

| High F | 3 (designated a, b, c) | natural plates (1 brand)* |

| High F | 1 | eco-friendly plates (sugar fiber is made with 100% non-toxic plant byproduct material) (1 brand) |

| Low Fc | 2 (designated a,b) | paper plates + eco-friendly food trays (>= 18% recycled wood fiber content) + poly coated freezer paper |

| Control | 2 | Whatman #2 filter paper |

| MSW-May | 2 (designated a,b) | fresh residential MSW collected May 2022 |

| MSW-August | 2 (designated a,b) | fresh residential MSW collected August 2022 |

Journal Articles on this Report : 3 Displayed | Download in RIS Format

| Other project views: | All 15 publications | 3 publications in selected types | All 3 journal articles |

|---|

| Type | Citation | ||

|---|---|---|---|

|

|

Titaley IA, De la Cruz FB, Field JA. Comment on “Release of Volatile Per-and Polyfluoroalkyl Substances from Aqueous Film-Forming Foam”. Environmental Science & Technology Letters 2020;7(11):866-8. |

R839600 (2020) R839600 (2021) R839600 (Final) |

Exit |

|

|

Titaley IA, De la Cruz FB, Barlaz MA, Field JA. Neutral per-and polyfluoroalkyl substances in in situ landfill gas by thermal desorption–gas chromatography–mass spectrometry. Environmental Science & Technology Letters 2023;10(3):214-221. |

R839600 (2023) R839600 (Final) |

Exit |

|

|

Ye Y, Titaley IA, Kim-Fu ML, Moll AR, Field JA, Barlaz MA. Release of volatile per-and polyfluoroalkyl substances from plant fiber-based food packaging and municipal solid waste to gas under simulated landfill conditions. Environmental Science & Technology 2024;58(48):21295-21304. |

R839600 (Final) |

|

Supplemental Keywords:

Landfill gas, emissions inventory, landfill model, food packaging, PFASProgress and Final Reports:

Original AbstractThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.

Project Research Results

- 2023 Progress Report

- 2022 Progress Report

- 2021 Progress Report

- 2020 Progress Report

- Original Abstract

3 journal articles for this project