Grantee Research Project Results

Final Report: Evaluating the Impacts of Nanomanufacturing via Thermodynamic and Life Cycle Analysis

EPA Grant Number: R832532Title: Evaluating the Impacts of Nanomanufacturing via Thermodynamic and Life Cycle Analysis

Investigators: Bakshi, Bhavik R. , Lee, L. James

Institution: The Ohio State University

EPA Project Officer: Hahn, Intaek

Project Period: January 1, 2006 through December 31, 2010

Project Amount: $375,000

RFA: Exploratory Research: Nanotechnology Research Grants Investigating Environmental and Human Health Effects of Manufactured Nanomaterials: A Joint Research Solicitation - EPA, NSF, NIOSH (2005) RFA Text | Recipients Lists

Research Category: Nanotechnology , Safer Chemicals

Objective:

Nanotechnology is a fast emerging field that is expected to move toward becoming a key player in influencing future global markets. When this project started, there was an urgent need to assess the broader environmental and societal implications in order to ensure a safe and sustainable nanotechnology industry. The use of a holistic approach like Life Cycle Assessment (LCA) that considers environmental impact of products or processes over their entire life cycle has been suggested by researchers to evaluate potential nanoproducts. However, LCA of nanotechnology poses several formidable challenges. These primarily include the severe lack of inventory data about nanomanufacturing processes and very little quantifiable data available on the human health and ecosystem impacts of products and byproducts of nanomanufacturing. LCA studies of potential nanotechnologies are especially important at early stages of research to evaluate the economic-environmental trade-offs among manufacturing processes and among alternative products to assist sensible engineering decision-making. The goal of this project was to establish life cycle inventory (LCI) modules and perform a traditional LCA for some common nanoproducts, such as vapor grown Carbon Nanofibers (CNF), titanium dioxide nanoparticles, and some of their applications. In addition to conventional LCA approaches, this work also aimed to utilize methods based on thermodynamics such as energy and exergy analysis.

Summary/Accomplishments (Outputs/Outcomes):

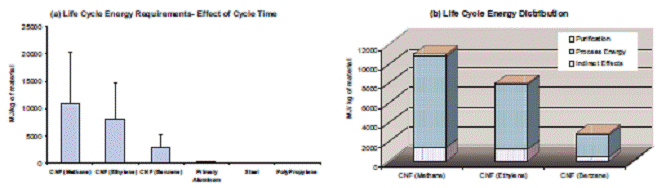

Figure 1. Lice cycle energy of analysis of carbon nanofibes CNFs (a) effect of cycle time (production cycle time ranges

from 1 hours to a continous operation for 300 days), (b) energy distribution along life cycle phases (Khanna et al., 2008)

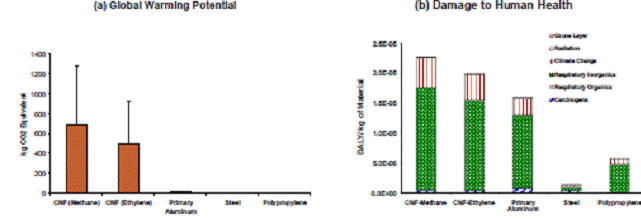

Figure 2. Vapor grown carbon nanofibers - life cycle assessment (VGCNF LCA) (a) global warming potential -

midpoint indicator (b) DALYs - damage indicator.

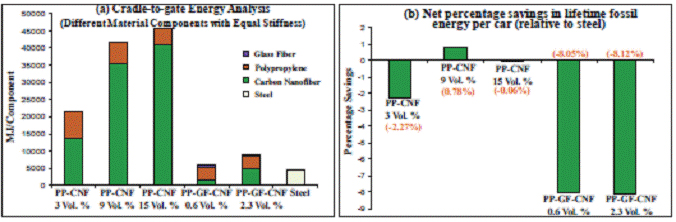

Figure 3. (a) Life cycle comparison of carbon nanofiber (CNF) reinforced polymer composits (a) material comparison

for equal component stiffness design (b) comparison of CNF polymer composites for automotive body panels

(Khanna and Bakshi, 2008).

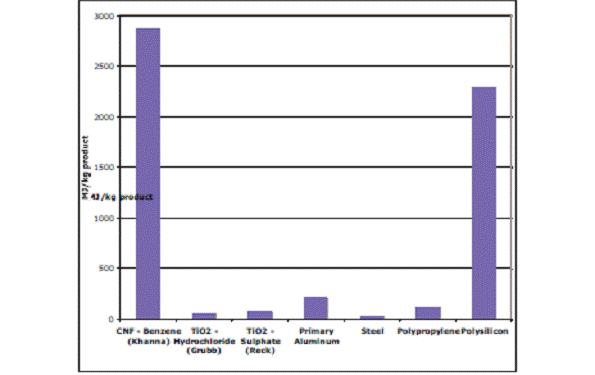

Figure 4. Per unit mass comparison of gross energy requirements for the hydrochloride process

with other building materials (Grubb and Bakshi, 2009).

Conclusions:

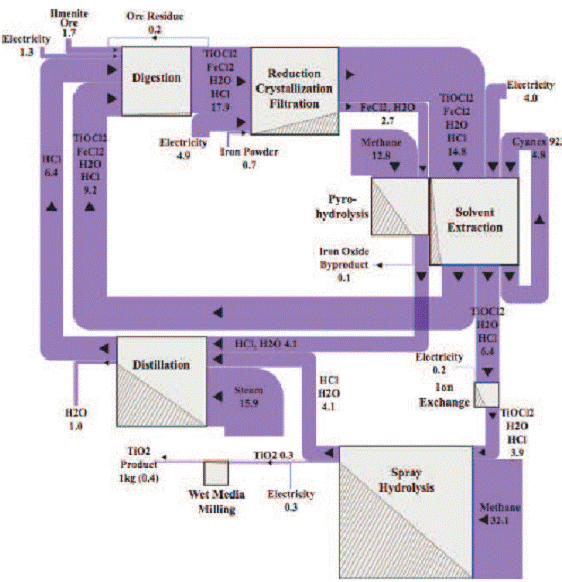

Figure 5. Grassmann diagram indicting the magnitude of all energy flows withing the process.

Units are all MJ of exergy/kg of product.

Journal Articles on this Report : 4 Displayed | Download in RIS Format

| Other project views: | All 19 publications | 5 publications in selected types | All 4 journal articles |

|---|

| Type | Citation | ||

|---|---|---|---|

|

|

Grubb GF, Bakshi BR. Appreciating the role of thermodynamics in LCA improvement analysis via an application to titanium dioxide nanoparticles. Environmental Science and Technology 2011;45(7):3054-3061. |

R832532 (Final) |

Exit Exit |

|

|

Grubb GF, Bakshi BR. Life cycle of titanium dioxide nanoparticle production: impact of emissions and thermodynamics of resource use. Journal of Industrial Ecology 2011;15(1):81-95. |

R832532 (Final) |

Exit Exit Exit |

|

|

Khanna V, Bakshi BR, Lee LJ. Carbon nanofiber production: life cycle energy consumption and environmental impact. Journal of Industrial Ecology 2008;12(3):394-410. |

R832532 (Final) |

Exit Exit Exit |

|

|

Khanna V, Bakshi BR. Carbon nanofibre polymer composites: evaluation of life cycle energy use. Environmental Science and Technology 2009;43(6):2078-2084. |

R832532 (Final) |

Exit |

Supplemental Keywords:

Life cycle assessment, carbon nanofibres, polymer nanocomposites, titanium dioxide, energy analysis, exergy analysis, life cycle inventory, Health, Scientific Discipline, ENVIRONMENTAL MANAGEMENT, Risk Assessments, Environmental Chemistry, Environmental Microbiology, Risk Assessment, nanomaterials, ecological risk assessment, environmental risks, human exposure, nanoparticulate aerosol, polymer nanocomposites, nanoparticle toxicity, nanotechnology, human health risk, carbon fullereneProgress and Final Reports:

Original AbstractThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.