Grantee Research Project Results

Final Report: Lightweight Green Roof Water Retention System

EPA Grant Number: SU835066Title: Lightweight Green Roof Water Retention System

Investigators: Spatari, Sabrina , Mickute, Monika , Zakutny, Matthew J

Institution: Drexel University

EPA Project Officer: Page, Angela

Phase: II

Project Period: August 15, 2011 through August 14, 2013 (Extended to December 31, 2015)

Project Amount: $75,000

RFA: P3 Awards: A National Student Design Competition for Sustainability Focusing on People, Prosperity and the Planet - Phase 2 (2011) Recipients Lists

Research Category: Pollution Prevention/Sustainable Development , P3 Awards , P3 Challenge Area - Safe and Sustainable Water Resources , P3 Challenge Area - Sustainable and Healthy Communities , Sustainable and Healthy Communities

Objective:

Typical North American vegetated roof systems consist of an expanded clay-based growing medium. The bulk density of these dry mixes ranges from 25 to 56 lb/sf (Wark, 2003). Depending on the structural conditions of an existing building, installation of a conventional vegetated roof can be cost prohibitive. Providing a reliable modular vegetated roof system weighing less than 10-12 lb/sf will render the roof affordable to the average homeowner and facilitate the introduction of green roofs on buildings across North America. The widespread application of more vegetated roofs in urban areas will result in benefits, including heat island effect mitigation, carbon sequestration, providing heating and cooling energy savings, and most importantly managing stormwater runoff by reducing impervious surface coverage while delaying peak runoff.

Relationship to People, Prosperity and the Planet

The Lightweight Green Roof (LGR) system was designed to deliver significant value to people. A cost effective, do-it-yourself (DIY) solution to storm water management will encourage average homeowners to personally participate in the current “Green Revolution” by easily retrofitting their properties with a lightweight vegetated roofing system.

The relevance and significance to the developing or developed world

The LGR will directly impact and benefit local, national, and global communities by providing all the benefits of a traditional vegetative roof system and heavily contributing to the improvement of the planet’s health. The Phase I research and results concentrated on solving local sustainability issues. The Phase II of the research continued the research and began developing a commercially viable product.

P3 Team project implementation as an educational tool

The LGR team has been participating in a Science Cafés Series organized by The Laboratory for Research on the Structure of Matter (LRSM), through the NSF-supported University of Pennsylvania Materials Research Science and Engineering Center (MRSEC). The Science Cafés, which are science talks for the general population about materials-related topic of current interest, are held at various locations in the Philadelphia region. An LGR Team member presented at Stoney’s Pub in Wilmington DE on January 16th, 2012 and World Live Café in Philadelphia on May 15th, 2013 to interested patrons. Presentation included basics of green roofs, their importance and the P3 research and its goals. We are hoping to make a repeat appearance and present an updated design of the LGR system in the spring of 2016.

Summary/Accomplishments (Outputs/Outcomes):

Cell design #1

Figure 1: Cell manufacturing using an Ultrasonic Welder

Initial LGR cell was designed and manufactured by our team in the spring of 2013. It consisted of already available green roof materials, such as J-drain water storage cups and filter paper, COLBOND water retention mats, geosynthetic fabrics, etc… These materials are made for a monolithic green roof installation and we chose to use them to create a modular system, as discussed in our previous reports. During our first full scale prototype installation we have learned that this system is rather inefficient in terms of both material cost and labor. In order to put together a single cell using an ultrasonic welder machine, it took 7 steps and approximately 25 minutes, once an operator was comfortable with the procedure. This process could be automated to some degree, but to set up a facility for such an operation would be rather costly. In addition, materials we used went up in price since we started this project. We were ordering limited quantities of raw supplies, therefore shipping costs added up and significantly impacted per unit cost of a finished product. Prior to project Phase II starting, we had estimated the cell to cost around $8 - $10 per square foot for raw materials. In the end it turned out to be $17.25 per square foot. This cost could be reduced if materials were ordered in larger quantities. However, unit price for a cell alone would be cost prohibitive to achieve our goal of a DIY system affordable by an average homeowner.

Figure 2: LGR Installation #1 in october 2013 and then in December 2015

The visual appearance of constructed cells need further work prior to putting on the market. In particular, the appearance diminished in quality after exposure to the elements over time (Figure 2). While we understand that roofs are rarely visible, we also know that homeowners would be more likely to install this system if it were visually appealing.

Our team deliberated and looked for ways to improve this design, but in the end we had reached a conclusion that this design will not become a commercially viable product. We looked back at what we had done. Using everything we had learned, our team worked towards re-creating the LGR cell in an entirely new way. The new design is discussed further in the report.

Medium Design #1

After learning more about the materials that make up the LGR soil medium, some of our peers as well as industry leaders expressed concerns about an environmental impact created by the mined materials of vermiculite and perlite, and the non-biodegradable EPS. Some of the concerns also included a potential of the EPS blowing away and spreading throughout the neighborhood. This further prompted a call to focus on re-thinking the material make-up of the Phase I formula, which is discussed further in this report.

Throughout the past year, since the full scale prototype #1 installation, data has been collected regarding our system’s insulating values, planting medium water retention capacity and water evapotranspiration as it relates to weather conditions and seasonal climate fluctuations. Below is a sample snapshot of data collected between 1/28/2015 and 11/5/2015 correlating the rainfall (blue) and soil moisture content (red) values.

Figure 3: LGR Cell Moisture Content (10/28/2015-11/5/2015)

After analyzing the moisture content and evapotranspiration within the LGR cell medium, we found that Rain is absorbed with in the planting medium right away, without any water shedding off the cell’s surface. This is ideal as the intent is to delay rain storm events by capturing 1st inch of the rain storm and alleviate storm water management burden from the storm sewer system.

As shown in the figure above, on 10/28/2015 total rainfall amounted to 1.1 inches (it was very light rain throughout the day). Because the light rain with frequent periods of no rainfall, our medium never reached full saturations (0.2-0.5 m3/m3). Maximum saturation value reached was 0.1702 m3/m3. This is indicative of well aerated and drained soil medium, which is ideal for sedum applications on the roof. Water which manages to drain through the soil medium then gets deposited into the bottom cell “cups” for additional long term storage.

Per above example, there was no rain between 10/30/15-11/4/15. As we had an unseasonably warm fall, temperatures ranged between high 40’s (night) and high 60’s (day). Even though moisture content was dropping consistently until the next rain event, moisture content values remained above 0.02 m3/m3. While this value represents a wilting moisture range for general crop plants, sedums need significantly less water to thrive and this range is acceptable.

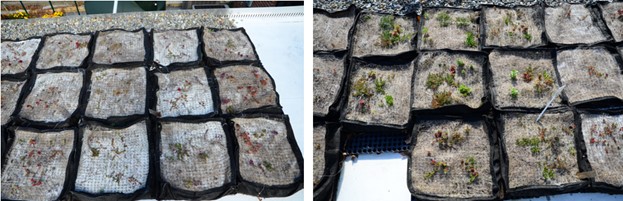

Figure 4: Sedum Plugs 4 months after installation. Left: LGR medium – sedum clipping rooted and are growing slightly, but they are not spreading. Right: Control cells with sedums growing much faster and spreading in coverage.

Sedum plant clipping were used, which took to our design planting medium right away. Observations were made periodically to assess the health and viability of the vegetation. As a control, we had also planted (8) cells with standard potting mix enriched with perlite for better water drainage. Prototype installation occurred in (2) stages: a portion was installed in May and the rest was completed in late June. Sedum clippings planted in May rooted much faster in the LGR medium than those planted in late June. Also, May clippings had a much better spread throughout the year than June ones. Regardless of when they were planted, LGR soil could not provide adequate nutrition to the plants for them to thrive. When compared to our control samples, LGR medium plants survived and multiplied slightly, but did not spread. Those in the control cells spread about 2 to 6 inches in diameter, which is typical for the species.

Our conclusion is that initial LGR planting medium consisting of Perlite, Vermiculite, and EPS sustains vegetation, but does not allow it to thrive. One option to overcome this issue might be populating LGR cells with fully grown plants. Another option is redesigning our planting medium.

Cell Design #2

Our initial cell design did not fail – on the contrary, it served as an invaluable learning experience. During numerous hours we spent manufacturing parts for the large scale prototype to be installed on BCAD’s roof, we gained knowledge of what will and what will not work.

Figure 5: Final LGR Cell design for plastic injection molding using HDPE plastic

We mistakenly thought we could use materials meant for monolithic system to assemble our modular DIY system. The manufacturing process turned out to be unrealistic. For the new design we decided to approach the problem from the manufacturability prospective. In the end it was determined that plastic mold injected parts would allow for cost effective and easily reproducible parts. Thinking back to our initial cell design and materials used, we developed an alternate design of a 1 square foot Leaner Greener Roof (LGR) cell, shown in the images to the right.

Figure 5 shows our final 3D model. It consists of a bottom portion, which, just like initial cell design, contains bottom cups to store additional water and filter fabric, and top frame encased in burlap to hold light weight medium. Sides remain perforated so that moisture and air can travel cell to cell. We had injection mold created, and going forward these parts can be reproduced fast and inexpensively, running about $5.00-$7.00 a set depending on volume ordered.

Figure 6: The same cell in showing vegetation spread in August 2015. Assembled revised LGR cell using revised LGR planting medium design and fully grown vegeation (manufactured in July, 2014)

With the new cell design our initial idea of creating a light weight green roof system is market viable once again. Plastic frames weigh 1.4 lb per set, which is slightly higher than we had anticipated. With our revised planting medium mixture, an entire assembly does not exceed 12 lb/sf when fully saturated. We will continue to research alternative mixtures as well as methods to reduce weight for the casing in order to meet the maximum of 10 lb/sf goal.

At this point we only have a square foot unit designed and manufactured, but once there is a market for it, we will develop alternate sizes and configurations along with sloped roof applications.

Medium Design #2

As previously mentioned, there were some concerns about the materials used in our planting medium design. In addition, based on prototype #1 observations made, initial planting medium design does not provide sufficient nutrients to plants for them to flourish, it only sustains the vegetation. At this point we were not able to replace perlite and vermiculite, but we concentrated our efforts towards replacing the most harmful component – EPS (expanded polystyrene). The EPS had no value added to the mixture other than increasing the volume with minimal weight impact. After experimenting with several materials, we determined that peanut shells will be more beneficial to the mixture by replacing harmful, non-renewable micro EPS. Peanut shells are a renewable material which is significantly less costly than the EPS. In addition, as peanut shells slowly decompose, they will provide organic content to the planting medium, allowing our vegetation grow and spread. This mixture was tested on our (4) cell prototypes and will be a part of a full installation this spring. We will follow similar procedures as we did with prototype #1 installed on BCAD roof. We will have a section of cells (about 10 sf) filled with regular well-draining soil as a control sample to compare vegetation growth and spread. We will also experiment with both – clippings as well as full grown plants to further establish better market-ready option.

The challenge with the new mixture is that peanut shells have a larger unit weight and they absorb more water than the EPS did. This, combined with the new shell design has put us 2 lb over our goal weight for the system, with a maximum weight of 12 lb/sf when fully saturated. 12 lb/ sf is still one of the lightest systems available in the market, but our research will continue refining the system until we reach our ultimate goal of the LGR system weighing less than 10 lb/sf when fully saturated.

Figure 7: Revised soil medium formula

Table above indicates the design values for the latest LGR cell design. During the design process, some observations were made.

- The LGR cell now weighs more than initially projected. In order to get closer to the maximum saturated weight of 10 lb/sf, formula had to be adjusted from 0.4/0.4/.08 (P/V/PS) to 0.35/0.35/0.6. This reduced the thickness of the cell, but difference is not significant.

- When the water was poured continuously on the cell, 0.4/0.4/0.8 cell reached the maximum weight of 11.5 lbs (however, it is critical to note that the water draining rate was significantly slower from the water dripping on the cell. This would only happen during the most severe rain storms). Once water on the cell was discontinued, water stopped dripping from the bottom of the cell about 5 minutes later and the weight leveled off at 9.2 lb.

- When the water was poured continuously on the 0.35/0.35/0.8 mixture cell, it reached the maximum weight of 10.0 lb (however, it is critical to note that the water draining rate was significantly slower from the water dripping on the cell. This would only happen during the most severe rain storms). Once water on the cell was discontinued, water stopped dripping from the bottom of the cell about 5 minutes later and the weight leveled off at 8.0 lb. This cell however, does not retain 5.2 lb of water, which means it would not absorb 1” of rain storm events.

- The final design will proceed with the 0.4/0.4/0.8 (P/V/PS) sold medium mixture.

Installation #2

Regretfully, the LGR team faced numerous counts of delays due to difficult policies enforced by Drexel University regarding off-site research projects and prototype installations. As a result of these delays, final materials (800 sf of plastic mold injected cells) were acquired in the late fall of 2015. Due to weather conditions, the LGR team is forced to wait until this April to proceed with the installation. Additionally, Drexel did not allow for th e2nd site to be a residential roof top, therefore a compromise was accepted by both – Drexel University and the LGR team.

Prototype #2 will be divided into two parts:

Figure 8: Prototype #2 installation

A portion of the prototype #1 (BCAD Roof) will be replaced with the prototype #2. This will allow us to monitor both prototypes side by side and continue collecting data via HOBO weather station already installed.

Another portion of the prototype (about 400 sf) will be installed at the ground level of a selected residential site. Ground level installation will allow for easy access and monitoring of the project. Installation is located on the south side with significant solar exposure, as it would have if on the roof top.

Figure 9: Prototype #2 ground level installation

Going forward, the LGR team will continue with the project at our own cost while continually looking for additional funding sources.

Marketability

We believe that revised LGR system is a market viable product. We will continue seeking funding and working towards this product release to the consumers.

When we conceived the LGR, we believed it to be a single product, which would be produced, sold, and installed as a unit. As research progressed and we revised our designs, potential market options also evolved. Once ready, we will be able to offer LGR system in several packages:

- Pre-Grown and fully assembled LGR cell – this can be sold through nurseries or other vegetative roof vendors. Target cost will be ~$12-$15 per sf. It can be offered as a lightweight system using LGR planting medium or as a traditional soil option.

- LGR case only – DIY type consumer can purchase cases only and use their own planting medium (like traditional soil) and their own vegetation. We see a large market potential in the educational community, where educators could teach green roof technologies and benefits through hands on workshops. Target cost will be ~$7-$9 per unit

- LGR planting medium – This can be sold separately, for those who decide to use a light weight option. Target cost will be $1-$3 per unit. If our revised planting medium proves to provide more nutrition to allow succulents to flourish, this can also be used for potted plants, especially those kept on the patios and balconies, where lightweight option might be more desirable.

The LGR research team was hoping to apply for a Small Business and Innovation Research Grant offered by the EPA, but unfortunately research topics for the last couple of years had been changed and stormwater management has been excluded. We are hoping that this topic will be included in the next year solicitation, but regardless our team will continue developing this project beyond EPA P3 program.

Conclusions:

EPA P3 program was an invaluable opportunity for students to develop products and evolve their green innovations. The LGR team is proud and honored to have had this unique opportunity to research light weight green roof options and demonstrate the possibility of a market viable product as the result of it. Even though the EPA P3 program has ended for the LGR team, we will continue to develop our ideas and vision to bring the LGR to average home owners.

Over the last several years, we have observed BCAD roof installation and altered both LGR cell and planting medium designs. At the end of this year we will be installing a second large scale prototype featuring our new ideas.

An updated cell design features black, 100% recycled HDPE plastic, which is injection molded. This process reduced labor as well as associated costs to mass produce the end product.

LGR planting medium has been altered and the harmful micro EPS has been eliminated. We were not able to reduce mined materials content to 50% as initially hoped, but we reduced it to 75% by weight from initial 90%. The research team will continue their efforts to further optimize the planting medium.

After installing and observing prototype #1, our team learned that the LGR system will not be market viable as initially designed. We had re-designed the cell and improved the planting medium, and we are now proud to declare, that this system has a strong market potential. We anticipate this system to not exceed $15/ sf, but we will relentlessly work to bring it down to $10/sf. The research team will continue to seek funding to further explore marketability options.

Journal Articles:

No journal articles submitted with this report: View all 2 publications for this projectSupplemental Keywords:

Building envelope, insulation, water retention, carbon reduction, carbon sequestration, heat island effect, sustainable water management, storm water management, green roof, energy conservationProgress and Final Reports:

Original AbstractP3 Phase I:

Lightweight Green Roof Systems | Final ReportThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.

Project Research Results

- 2015

- 2014 Progress Report

- 2013 Progress Report

- 2012 Progress Report

- Original Abstract

- P3 Phase I | Final Report