Grantee Research Project Results

2010 Progress Report: Cool Roof Coatings Incorporating Glass Hollow Microspheres for Improved Solar Reflectance

EPA Grant Number: SU834300Title: Cool Roof Coatings Incorporating Glass Hollow Microspheres for Improved Solar Reflectance

Investigators: Barsoum, Michel , Eisele, Eric , Hagarman, James

Current Investigators: Barsoum, Michel , Biamah, Michael , Jerbarsi, Anthony , Kocher, William , Kownurko, Devin , Krall, Ryan , Mox, Daniel , Wilson, Mathew , Zoules, Dimitri

Institution: Drexel University

EPA Project Officer: Page, Angela

Phase: II

Project Period: August 15, 2009 through August 14, 2011

Project Period Covered by this Report: August 15, 2009 through August 14,2010

Project Amount: $61,829

RFA: P3 Awards: A National Student Design Competition for Sustainability Focusing on People, Prosperity and the Planet - Phase 2 (2009) Recipients Lists

Research Category: Pollution Prevention/Sustainable Development , P3 Awards , Sustainable and Healthy Communities

Objective:

Solar gain is in part responsible for up to 56% of energy consumed by cooling systems in residential buildings1. Additionally, high building density in the urban environment contributes to the urban heat island effect. According to the EPA2, regions exhibiting the urban heat island effect can be as much as 10º F warmer than their rural counterparts, and these regions may see as high as a 22º F difference in temperature between day and night. Mitigating the urban heat island effect has the potential to reduce cooling demand, peak demand, and heat related illnesses and fatalities.

By applying cool roof coatings to a building's exterior, cooling loads can be reduced and urban heat islands can in part be mitigated.3 Many commercially available cool roof coatings are white paint formulations based on titanium dioxide, TiO2.4 Although TiO2 and other pigments are effective at scattering visible wavelengths, they exhibit strong absorption in the infrared region.5 By incorporating controlled voids in a coating as the scattering medium, the void size distribution can be optimized for broadband radiation scattering.6 During our P3 Phase I, a coating utilizing glass hollow microspheres, GHM, as a means of controlling void diameter was developed. The objective of Phase II is to subject the developed roof coating to weathering tests, ASTM reflectivity and mechanical testing, additional field-testing, and any necessary re-formulations. The cool roof coating P3 project continues to engage undergraduate students in research at Drexel. Over the last several months, an undergraduate Chemistry freshman student gained exposure and training in the Chemistry department’s analytical instrumentation labs while working on the project. Freshman design teams, underway this coming quarter, are being encouraged to study how different cool roof coating formulations impact the return on investment and ultimate lifetime of a roof, among other topics.

The College of Engineering at Drexel University hosted the annual Engineer’s Week events in February, 2010. This year, 75 inner city high school students attended the annual High School Day, part of Engineer’s Week. The P3 Cool Roof Coating project was featured at this event as an example of how students can translate classroom concepts into research activities in a university setting.

The Department of Materials Science and Engineering, in collaboration with ASM International, will be hosting Materials Camp in June, 2010. During this week long event, 24 high school students interested in pursuing careers in Materials Science and Engineering will be engaged in laboratory activities at Drexel’s campus. The P3 Cool Roof Coating project will be featured as a lab demonstration at this event.

Progress Summary:

The purpose of last year’s research was to establish formulations which meet ASTM and California Energy Commission Title 24 requirements. Although coatings formulated with glass hollow microspheres consistently surpass reflectivity standards, the incorporation of the large spherical particles can negatively impact the strength and mechanical properties of the coatings significantly. Additives can be used to increase the strength of the binder matrix; this past year’s testing focused on establishing the relationships between additive concentrations and the mechanical properties of GHM containing polymer films.

Elastomeric cool roof coatings were formulated using GHMs supplied by Potter’s Beads and the 3M Corp. Early samples prepared during phase I exhibited surface temperature decreases as much as 5ºC compared to TiO2 pigmented white control samples. These samples also achieved a reflectance of 91% at 10% volume loading microspheres using ASTM Standard C-1549, performed by Dow Chemical.

Samples prepared previous to December 2009 were formulated using a low cost polystyrene acrylate binder, which resulted in poor tensile strengths presumably due to poor interface bonding between the spheres and binder. These samples exhibited an average tensile strength of 33 psi (ASTM standards require 100 psi).

After testing over 76 formulations, we found that the combination of zinc oxide, ZnO, and silane additives were needed to achieve the necessary tensile strengths. The new series of samples was formulated using a 100% acrylic binder (55% solids, 350 nm particle size, Rohm and Haas Rhoplex EC-1791) and the following improved coalescent formulation: coatings were formulated using 15% volume fraction 13 µm glass spheres and were drawn down in two layers on silicone paper. The first layer was left to dry for 24 h before application of the second layer. Free coatings were dried for a minimum of four days per side, cut into 30mm x 7mm pieces, and tensile tested in triplicate.

Dow Xiameter silanes 6040 (Glycidoxypropyltrimethoxysilane) and 6020 (Aminoethylamino-propyltrimethoxysilane) were added to the 15% sphere volume fraction and drawn down immediately after mixing using the following procedure: 1) Apply a 35 mil coating to silicone release paper, 2) trim away edges and apply a second 45 mil layer 24 hours later, 3) Trim and release coating from substrate and flip over 72 hours later, 4) cut into 25mm x 6.4mm strips, and tensile test each coating in triplicate. Tensile testing samples three times each reduced the complications due to human error in sample preparation and bubbles in the coating, etc. In all, 252 tensile tests were conducted on a total of the highest performing silane sample exhibited a 36 % improvement in tensile strength, compared to the average tensile strength of the controls. A similar improvement was found using slightly less silane (Z6020) and allowing the coating to set for 96 h before draw down. This could be due to the slow bonding kinetics between the spheres and the silanes, at the low concentration used here. Formulations using silanes at concentrations greater than 0.4 % exhibited complete gelation, or hardening, at room temperature in sealed containers within one week. Although silane addition is an effective method to increase tensile strengths, adding the material directly to the formulations will likely impact the long term shelf life of the coatings. Future work will include other methods of silane incorporation.

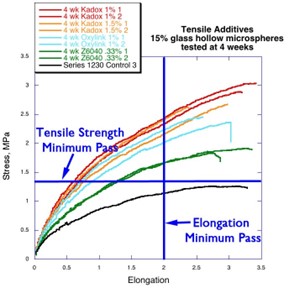

Figure 1. Stress Strain curve for select tensile additive coatings containing 15% wt volume glass hollow microspheres. All samples containing additives evaluated pass ASTM D6083 standard for elognation (200%) and tensile strength (200psi).

ZnO is typically used in paints and coatings for it’s crosslinking activity in acrylic formulations. Several formulations were evaluated containing ZnO nanoparticles (Buhler Oxylink, 50 nm mean). Samples containing 1-1.5 wt.% nanoparticle dispersions exhibited as much as a 57% increases in tensile strengths. When a ZnO pigment, in powder form, was used instead, the tensile strengths increased a 69%. This significant increase is again likely due to the reinforcing properties of the irregular ZnO particles, as well as the cross-linking activity of the ZnO. The relationship between the tensile properties of the coatings containing ZnO nanoparticles and ZnO powders is compelling evidence that ZnO lends more than reinforcement to formulations, and that significant tensile strengths improvements can be obtained. Additionally, the ZnO particles exhibit UV reflectance, which should ultimately extend the lifetime of the coating due to decreased photo-aging of the polymer.

Since significant improvements in tensile strengths were achieved with ZnO, the use of silanes will likely be discontinued due to significant handling precautions and limited shelf life of the coatings. Furthermore, since nanoparticle dispersions are more expensive and given that their ecological impact is not well understood at this time, future formulations candidates will not include the nanoparticles; ZnO powders work as well and will be used instead.

DE was investigated as a visible/IR reflective coating filler. As noted above DE is a low cost, natural material with a predictable, repetitive microstructure. The material can be incorporated into a coating to create voids, which then scatter light. Several coatings were formulated, and found to exhibit high reflectance (~ 97% ) in the UV, VIS, and NIR regions. however, this reflectance was only achieved at high volume loadings. Four candidate coatings containing DE were formulated to pass standard tensile tests. Unfortunately, the reflective properties diminished as the DE volume loading was decreased to meet the tensile standards. The results, however, suggest that optimum GHM/DE combinations exist that would, i) perform better than TiO2-based formulations and, as important by, ii) cheaper. The latter is an important consideration. During the second year of this project this avenue will be perused.

Future Activities:

Elastomeric cool roof coatings containing GHMs and a variety of additives have been formulated and found to exhibit solar reflectance over the entire solar spectrum of upwards of 91%. These coatings, were simultaneously well within strength requirements detailed by ASTM and CEC Title 24 standards. Furthermore, these coatings were found to exhibit high UV reflectance, a desirable quality in coatings since photo degradation is prevented, extending the lifetime of the Double layer coating systems will be investigated in the summer of 2010 since a 2 coat system can be developed with a strong base and a highly reflective glass hollow microsphere top layer. By balancing the properties of these two layers, a low cost formulation with optimal properties is possible.

During the past year we have shown that while silane additives used directly in formulations successfully increased the tensile strengths, even more significant gains were realized by the addition of ZnO powders. The high activity of the silanes decreases the shelf life of the formulations; other methods of coating spheres, using minimal amounts of the silanes, will be explored (e.g. thermal evaporation and solvent washing). The addition of 0.5% of ZnO powders or nanoparticles significantly increased the tensile strengths; future formulations will now incorporate 1.5% wt ZnO powders.

Diatomaceous earth coatings exhibit promising potential, however more formulation work must be conducted to increase the reflective properties of the coatings at low DE loadings. This will be done by sourcing a larger sampling of diatom species and applying processing techniques such as ball milling and high shear mixing to the raw materials to try and tailor the particle size distribution for optimal reflectance.

Double layer coating systems will also be investigated in the summer of 2010 since a 2 coat system can be developed with a strong base and a highly reflective GHM top layer. By balancing the properties of these two layers, a low cost formulation with optimal properties is possible. Current candidate formulations are being sent to Dow Chemical for full analysis and testing including accelerated weathering, adhesion, low temperature elongation, permeance, water swelling, and emissivity in early April. Early results should be received by mid April, with the all important accelerated weathering testing data available in May or June. coating.

References:

- DOE. 2007 Buildings Energy Data Book, U.S. Department of Energy. http://buildingsdatabook.eren.doe.gov/

- Environmental Protection Agency. "Reducing Urban Heat Islands: Compendium of Strategies" Retrieved March 12, 2009. https://www.epa.gov/heatisland/resources/ pdf/BasicsCompendium.pdf

- Environmental Protection Agency. "Reducing Urban Heat Islands: Compendium of Strategies - Cool Roofs" Retrieved March 12, 2009. https://www.epa.gov/heatisland/resources/pdf/CoolRoofsCompendium.pdf

- J. Beltley and G. P. A. Turner, Introduction to Paint Chemistry and Principles of Paint Technology, 4th ed. (Chapman and Hall, London, 1998), p. 105-106, 110.

- Cole, Joseph R; Halas, N.J. Optimized Plasmonic Nanoparticle Distributions for Solar Spectrum Harvesting. Appl. Phys. Lett. 89, 153120 (2006).

- Dombrovsky, Leonid A; Randrianalisoa, Jaona H; Baillis, Dominique. IR radiative properties of polymer coatings containing hollow microspheres. Intl. J. of Heat and Mass Trans. 50 (2007) 1516–1527

Supplemental Keywords:

Titanium Dioxide, IR reflective pigments, cool roof coatings, urban heat islands, Energy StarRelevant Websites:

Progress and Final Reports:

Original AbstractP3 Phase I:

Cool Roof Coatings Incorporating Glass Hollow Microspheres | Final ReportThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.