Grantee Research Project Results

Final Report: Design and Testing of a Point of Use Electrolytic Chlorine Generator for Drinking Water Disinfection in Poor Countries

EPA Grant Number: SU834013Title: Design and Testing of a Point of Use Electrolytic Chlorine Generator for Drinking Water Disinfection in Poor Countries

Investigators: Just, Craig , Keenan, Alexandra , Bang, Thomas , Krausman, Ted , VanFosson, Alex

Institution: University of Iowa

EPA Project Officer: Hahn, Intaek

Phase: II

Project Period: August 15, 2008 through August 13, 2010 (Extended to August 13, 2011)

Project Amount: $75,000

RFA: P3 Awards: A National Student Design Competition for Sustainability Focusing on People, Prosperity and the Planet - Phase 2 (2008) Recipients Lists

Research Category: P3 Challenge Area - Safe and Sustainable Water Resources , Pollution Prevention/Sustainable Development , P3 Awards , Sustainable and Healthy Communities

Objective:

Design: The current concept will be demonstrated to partners in the developing world to gain feedback on usability and to developed world partners to maximize affordability. With this input, the design will be modified to maximize the central constraints of usability, sustainability and affordability.

Manufacture: 100 chlorine generator kits will be manufactured and transported to the chosen developing world region –most likely a partner community in Mexico or Haiti with whom the University of Iowa has an established relationship. International Water Management Systems is already working in Mexico and Haiti. Konpay, Inc., in Haiti, may also be a valuable partner.

Education: Instructions will be developed in Spanish and/or Creole along with initial personal instruction to educate residents about the importance of purifying drinking water and how to use their chlorine generation system.

Summary/Accomplishments (Outputs/Outcomes):

Design

Water Bottle Housing with External Power Generator

Our best Phase I working model reaction cell used for testing was a simple, 10 oz, plastic water bottle, with the electrode fitted to the cap (Figure 1). The anticipated cost of materials to produce an initial run of this design is approximately $8 per unit. The cost per unit to produce boxcar quantities could easily be as low as $5. This unit tested by a focus group in Xicotepec, Mexico, in March of 2009 and it was thought to be effective, but cumbersome.

Manufacturing

Figure 1: Water bottle housing prototype with external power generator.

The “Next Generation” Prototype

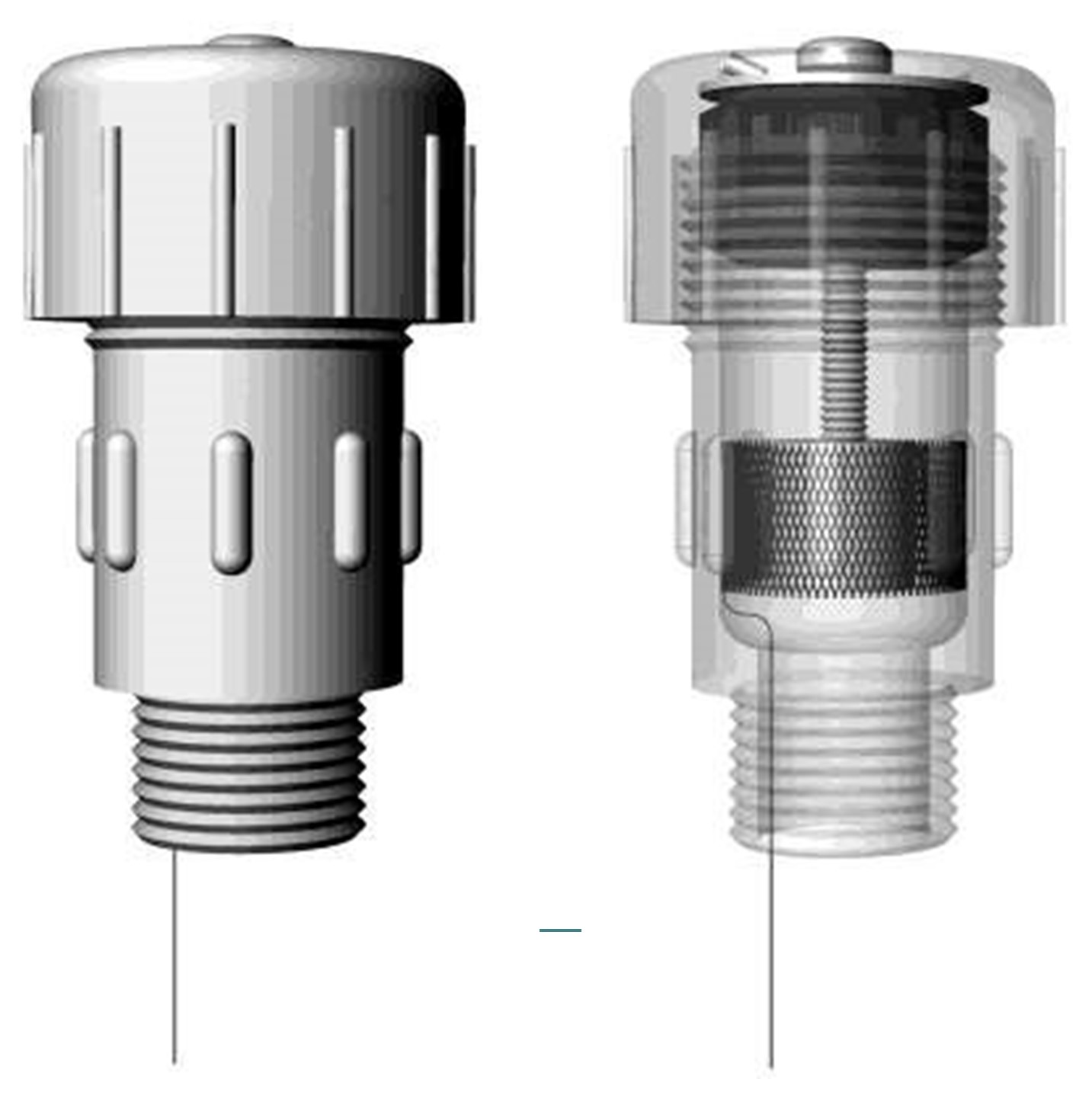

Much of the Phase II progress to date has focused on the creation and testing of the “next generation” handheld chlorine generator that takes advantage of a more sophisticated cell geometry (Figure 2) while maximizing usability and minimizing cost. This new prototype has also been designed with manufacturability in mind.

Figure 2: The “next generation” chlorine generation cell prototype made from easily found plumbing supplies.

The “Next to Last Generation” Prototype

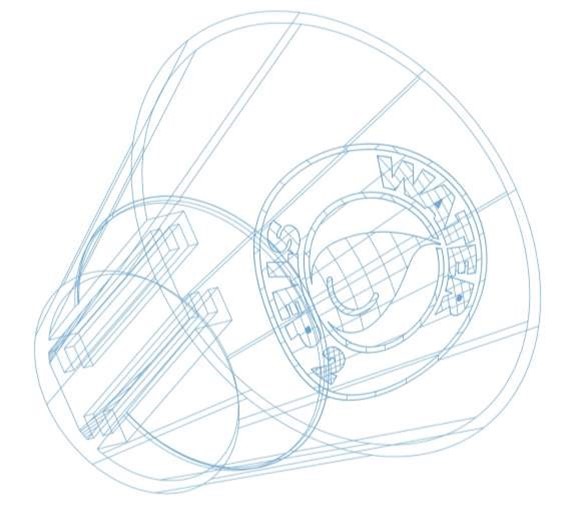

Figure 3: The "next to last generation" prototype design drawings.

The “next to last generation” prototype was designed using Inventor software and then “printed” using a 3D, hot plastic prototyping machine. The key elements to the design (Figures 3 & 5) include an ergonomic cup shape with built in slots for the electrodes. The base the cup is sized such that depositing “one layer” of salt on the bottom will be the appropriate amount for bleach generation. The cup is filled about half way with water and a simple 6 volt lattern battery (or equivalent) is used to power the device for four minutes until about 1000 ppm bleach is produced (Figure 4).

Figure 4: Chlorine production over time.

Figure 5: Photographs of the “next to last generation” prototype with accessories.

The Final Prototype and the Partnership with a New Non-Profit

The final step in this process was to modify the existing plastic prototype such that is would be optimized for manufacturing. We worked with Jasper Rubber in Indiana to produce the design file corresponding to the image below (Figure 6). Only slight modifications were made to the prototype – the large notch in the cup was removed and the logo for Water: Step 2 was added.

Figure 6: The final prototype with the Water: Step 2 logo.

The Water: Step 2 non-profit has been formed under the direction of Mark Nagan of Naples, Florida. This non-profit has just recently invested over $10,000 to have a mold made for the cup as required for the injection molding process. With the mold in place, the non-profit will be in a position to make thousands of the cups in a very short amount of time. Water: Step 2 has also made contact with Corrpro Company in Ohio and has made an agreement to purchase the electrode material at a reduced cost.

Conclusions:

The final handheld bleach generator prototype was developed and tested at the University of Iowa in the fall of 2011. The partnership with the newly formed non-profit Water: Step 2 was cause for delay in the preparation of the final report for this project. But, we feel the delay was worthwhile given that we can now report that a mold is being created for the mass production of the plastic cups required for the manufacture of the device. Water: Step 2 also intends to be the world-wide distributor of the device.

It should be noted that perchlorate can be produced via electrolysis of salt water. Perchlorate is a known human toxicant and therefore should not be added to drinking water. We had the bleach from the handheld chlorinator tested by Keystone Laboratories and the results showed no presence of perchlorate above 4 parts per billion (i.e. non detectable).

We can also report that the device has been well received by the people of Kobriti, Ghana. Per Institutional Review Board protocols, we aren’t able to distribute the device or use the bleach generated from the device as a health intervention. But, the functionality of the device and the design has been deemed appropriate by our focus groups in Kobriti. This bodes well for the long-term use and sustainability of the device.

Progress and Final Reports:

Original AbstractP3 Phase I:

Design and Testing of a Point of Use Electrolytic Chlorine Generator for Drinking Water Disinfection in Poor Countries | Final ReportThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.