Grantee Research Project Results

Final Report: Making Construction Materials from Forest Biomass, Recycled Cellulose and Geopolymers

EPA Contract Number: 68HERC25C0029Title: Making Construction Materials from Forest Biomass, Recycled Cellulose and Geopolymers

Investigators: Fuller, Barry J

Small Business: BetR-blok, LLC

EPA Contact: Richards, April

Phase: I

Project Period: December 16, 2024 through June 15, 2025

Project Amount: $100,000

RFA: Small Business Innovation Research (SBIR) - Phase I (2025) RFA Text | Recipients Lists

Research Category: Small Business Innovation Research (SBIR)

Description:

BetR-blok® (better block) is a new product with limitless potential as a replacement for wood, concrete, and foam building materials to lower embodied carbon in the built environment. It is entirely made from recycled cellulose, including forest biomass, requires comparatively little energy to produce, and has a small environmental footprint. Using forest biomass helps reduce methane buildup, reducing forest fires. Recent research suggests that geopolymers may be used as a substitute binder in BetR-blok, replacing Portland cement. Eliminating Portland cement is a positive step toward reducing greenhouse gases.

Summary/Accomplishments (Outputs/Outcomes):

Summary of Findings & Conclusions

Phase I research has been of two types: Basic and Applied. The Basic research has involved working with mix constituents and material properties to finalize the best possible mix - including some beginning work with geopolymers. The Basic research resulted in two major findings so far: 1.) it confirmed that our current mix formula is the best that it can be until an alternative for Portland cement can be found and 2.) it proved that at least one type of geopolymer mix currently available is compatible with our production system. This was a critical discovery because earlier examinations of geopolymer mixes seemed to indicate that major equipment modifications or complete system replacement might be necessary to enable the use of geopolymers. However, there is much more research to be done in order to insure that this geopolymer mix is the best for our intended use. That will be done in Phase II.

The Applied research was varied. It included rounds of iterative field tests involving equipment and system modifications intended to improve production speed, consistency and quality. These trials and field tests focused on production automation, materials handling, portioning, agitation, timing, compression and curing. Significant work on the following equipment and sub-systems was done.

Pulper power, blade design and rotational speed: Different feed stocks required adjustments in these parameters to render uniform pulp consistency and flow rate. At this time, one mix is already settled upon and ready for commercial application. Another, involving geopolymers, is under examination/review and should be ready in a few months.

Hose screw conveyor: The hose screw conveyor underwent many trials involving the optimization of inlet volume speed, positioning and height. A custom device had to be fabricated and tested which allowed adjustment in location of the drive and motor relative to the mixer in four directions: near/far, left/right, up/down and tip. In other tests, the inlet end of the conveyor hose was reduced and enlarged to find the optimum adjustment for material feed and dust suppression.

Dump bed: A dump bed was added to the company truck to make it easier to unload recycled newspaper and other materials like forest biomass. The truck is backed up to a self-tipping hopper which is standing on a large platform scale. The bed is pushed up on one end by a hydraulic cylinder, causing the recycled materials to fall into the hopper where portions are weighed. The self-tipping hopper is then lifted in the air with a forklift and dumped into the pulper.

Automation research: The automation research was quite far reaching and involved integrating the operation of individual pieces of equipment into subsystems, and then combining the subsystems into the entire production system. Final automation testing is in progress.

Wireless access and security system: Since complete system integration involves moving all the equipment outside, it was decided that a sophisticated security and monitoring system be installed for watching the system when it was unattended and for enabling rapid troubleshooting from remote locations. The system installed is password protected and allows anyone with proper credentials to monitor the entire system. Four cameras can be moved remotely to look at different areas of a scene. A fifth is a “floating camera” which can be used to “go inside” equipment in order to follow troubleshooting paths.

Baby press modification: The baby press is used to conduct experiments requiring mix test samples. The samples are prepared in groups of six. Three of the group are vetted at the BetR-blok laboratory and the best groups of three are sent to an independent outside laboratory to confirm in-house results. The baby press was having difficulties with preparing geopolymer samples. It seemed that pressing them to a given volume requires more force than samples prepared with Portland cement. The baby press was pressing so hard that the pressing box was deflecting - actually bulging out during load testing. That was changing the shape of the sample and spoiled the test results. A way has been found to reinforce the baby press so that test results are valid.

Portland cement holding hopper modification: The Portland cement holding hopper is being substantially altered to use a flexible hose screw conveyor system to move cement, geopolymers or other powdered hardeners. The changes are positive from the energy consumption standpoint as the holding hopper will no longer require a drive and power system -including a 3 HP motor. That power will be provided by the screw conveyor itself. The changes will also simplify the hopper considerably in that it will not require any automation for weighing or portioning. Those functions will also be handled by the screw conveyor.

Conclusions:

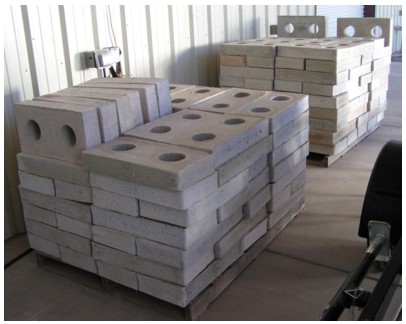

BetR-blok is beyond the concept stage, very near commercialization. Research to date has proven that the basic process is technically feasible. Significant previous research and financial support has come from Arizona State University, the United States Forest Service, the Edson Foundation, local utilities, and private donors. A unique BetR-blok proof-of-concept manufacturing system that produces blocks made from recycled paper and other cellulose is nearing completion. These blocks have been engineered and approved for home construction. An experimental structure has been built and monitored. Successful testing has been done on producing mixes combining recycled cellulose with forest waste. Planning is underway, which would extend into Phase II, for making blocks, sheets and dimensional lumber with BetR-blok mix - using geopolymers as a binder - which will be a significant breakthrough.

Compared to other concrete building products, BetR-blok is a much better insulator and has many other valuable properties. It is less expensive, easier on the environment and, potentially, much more versatile than its competitors. One mix may be used to produce multiple types of building materials.

The only barrier to commercialization is finalizing mix research, and finishing & stress testing the proof-of-concept manufacturing system. Phase II plans include the transition to geopolymers as a binder and scaling for market launch with the addition and testing of large capacity, automated machinery.

We already have the, experience, expertise, much of the equipment and an extensive cooperative research network from earlier grant work, including the resources of Arizona State University (ASU), to make this happen.

The potential of this project is inestimable - it would result in a new paradigm for manufacturing a wide range of inexpensive, environmentally-friendly building materials.

The perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.