Grantee Research Project Results

Final Report: Fighting Fires with Filters - Electrospinning Biodegradable Materials for High-performance Indoor Air Filters

EPA Contract Number: 68HERC24C0015Title: Fighting Fires with Filters - Electrospinning Biodegradable Materials for High-performance Indoor Air Filters

Investigators: Pallotta, Michael

Small Business: DiPole Materials, Inc.

EPA Contact: Richards, April

Phase: I

Project Period: December 1, 2023 through May 30, 2024

Project Amount: $100,000

RFA: Small Business Innovation Research (SBIR) - Phase I (2024) RFA Text | Recipients Lists

Research Category: Small Business Innovation Research (SBIR) , Air , Wildfires , Air Quality and Air Toxics

Description:

DiPole Materials, an advanced materials manufacturer, was awarded a Phase I SBIR contract from the EPA to develop a biodegradable indoor air filter media made from electrospun nanofibers, bio-eAFs, that could be used to effectively remove harmful particulates (PM2.5) and volatile organic compounds (VOCs) from the air, especially during high-pollution events such as wildfires. In this six-month effort, DiPole achieved target objectives of 1) Identifying ideal electrospun, bio-degradable materials for use as air filtration media in bio-eAFs, 2) Upgrading the performance (particle filtration efficiency and pressure drop) of candidate bio-eAF materials, and 3) Developing an air filtration cartridge prototype incorporating bio-eAFs.

Summary/Accomplishments (Outputs/Outcomes):

In this work, DiPole applied expertise in materials science, polymer chemistry, and manufacturing nanofiber materials to compile a list of bio-friendly polymers that could be electrospun into a nanofiber filter membrane, conduct preliminary electrospinning experiments with those polymers, and acquire enough data to select two bio-friendly polymers as final candidates of bio-eAFs. DiPole then conducted designs of experiments with the two candidate bio-eAF materials to optimize their particle filtration efficiency (PFE) and pressure drop. DiPole also incorporated additives that can remove VOCs into the nanofiber filter membrane. Finally, DiPole developed a bio-polymetric air filter cartridge using bio-eAFs as the filter media, began building a cartridge filter testing rig that can assess the PFE and pressure drop of a 12” x 12” x 1 cartridge filter, and acquired third-party data verifying the competitive performance of the bio-eAFs compared to commercial state-of-the-art air filters.

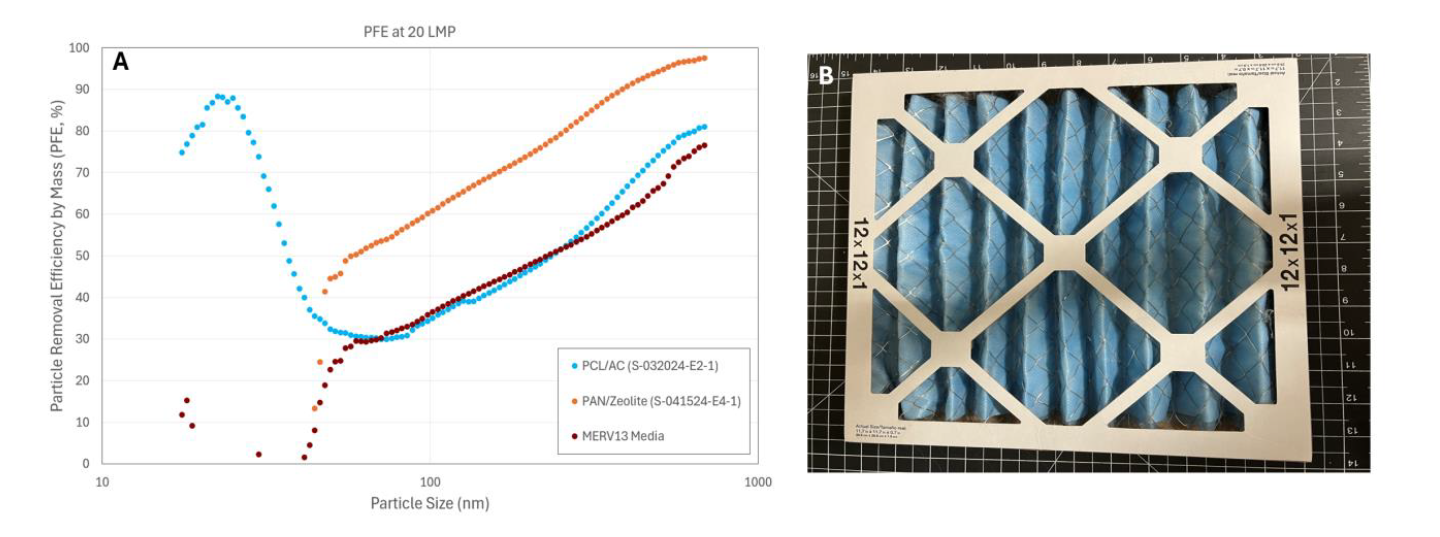

DiPole successfully produced an indoor air filter made from an electrospun biodegradable polymer, polycaprolactone (PCL). This material can be easily combined with materials that are known to trap VOCs in a composite filter. For instance, when combined with activated carbon (Aries Filterworks SP-05-1040), DiPole found the electrospun composite has an equivalent particle filtration efficiency (PFE) for aerosols generated from by simulated wildfire (wood smoke), as does a MERV 13 rated material at 20 LPM (blue and red data points, respectively). Furthermore, DiPole’s eAFs, made from polyacrylonitrile (PAN) and zeolites (Beta Zeolite Powder, 0.55-0.70 nm pores MR 40), were able to outperform a commercial MERV13 filter at 20 LPM (orange). Of unique interest, is the bio-eAFs’ high efficiency at removing wood smoke particles that are < 100 nm. These particles are known to pose a threat to human respiratory health, having been linked to a higher incidence of atherosclerosis and the exacerbation of asthma and airway inflammation. Lastly, DiPole successfully developed a prototype indoor air filter product, which incorporated the bio-eAF media into a 12” x 12” x 1” HDX filter cartridge housing. DiPole also made a schematic and began building a particle filtration testing rig for assessing the particle filtration efficiency (PFE) of the 12” x 12” x 1” bio-eAF prototype.

Figure 1. A-Particle Filtration Efficiencies (PFEs) of two electrospun filters, including the bio-eAF from PCL and Activated Carbon (blue) and the eAF from polyacrylonitrile and zeolites (orange), as well as commercial MERV13 filter (red) using aerosol particles derived from wood smoke (davg. = 150 nm) at an airflow of 20 LPM. B-Dipoles’ bio-eAF in a MERV testing unit.

In addition to making technical strides in developing a bio-friendly electrospun filter media capable of filtering PM2.5 and VOCs generated from wildfires, DiPole developed relationships with several potential commercial partners in the indoor air quality and HVAC filter space. Three potential clients expressed interest in DiPole’s ability to electrospin a bio-friendly filter media that could be integrated into one of their products or replace the current filter media of an existing product and remove VOCs from the air. Each of these companies was interested in the bio-eAF for a variety of reasons, including improved filter efficiency resulting in a reduction of the overall material cost of their current products; improved HVAC system efficiency and lower carbon footprint due to the bio-eAFs’ lower pressure drop and higher porosity; and potential replacement of Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) filter media used in existing commercial filter products.

Conclusions:

After successfully creating a prototype of the bio-eAF, DiPole envisions two potential routes for a final commercial product. First, based on ongoing customer discovery conversations, DiPole believes a filter media made from bio-friendly polymers, such as PCL, and/or a PFAS-free polymer, such as PAN, that can remove both PM2.5 at an efficiency >95% and VOCs generated from wildfires would have significant value in the air filtration market. Each potential commercial partner DiPole spoke with expressed great interest in a filter media that could mitigate the harm caused by VOCs generated by wildfires and could be easily incorporated into a cartridge filter housing. Second, DiPole sees clear commercial value in a standalone filter media made from bio-friendly and/or PFAS-free polymers that can be used to replace the materials currently used in the MERV 11-14 filter range. A filter media made from bio-friendly electrospun nanofibers (bio-eAFs) would make for a more energy efficient HVAC system with a lower carbon footprint, due to the lower pressure drop and improved porosity of the nanofiber filter.

SBIR Phase II:

Fighting Fires with Filters - Electrospinning Biodegradable Materials for High-Performance Indoor Air FiltersThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.