Grantee Research Project Results

2013 Progress Report: Don't Eat Your Spinach: Nature Inspired Biohybrid Solar Cells

EPA Grant Number: SU835287Title: Don't Eat Your Spinach: Nature Inspired Biohybrid Solar Cells

Investigators: Jennings, G. Kane , Anilkumar, Amrutur V.

Institution: Vanderbilt University

EPA Project Officer: Hahn, Intaek

Phase: II

Project Period: August 15, 2012 through August 14, 2014 (Extended to August 14, 2015)

Project Period Covered by this Report: August 15, 2012 through August 14,2013

Project Amount: $88,992

RFA: P3 Awards: A National Student Design Competition for Sustainability Focusing on People, Prosperity and the Planet - Phase 2 (2012) Recipients Lists

Research Category: Pollution Prevention/Sustainable Development , P3 Awards , P3 Challenge Area - Air Quality , P3 Challenge Area - Chemical Safety , Sustainable and Healthy Communities

Objective:

The 3-member 2012-13 EPA P3 design team sought to optimize a single solar cell that incorporates a PSI film on highly p-doped silicon. This project involved

- Optimizing the transparent counter electrode

- Optimizing the mediator species

- Reducing the electrode separation to the scale of a few microns in order to investigate the effect of mediator diffusion path length on solar cell performance

Progress Summary:

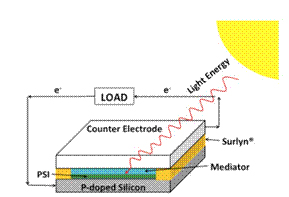

Design and Procedure. The basic design for the silicon-based solar cell consisted of a working electrode, a thin film of PSI, an electrolyte and mediator solution, a transparent electrode, and Surlyn® tape, which acts as a spacer between the electrodes. Figure 1 shows a basic schematic for the working solar cell. In this design, light causes electrons to be transferred from PSI to mediator molecules, which in turn transfer the electrons to a transparent anode. Positively doped Si transfers electrons back into PSI so that the process can be continually cycled.

Figure 1. A basic schematic solar

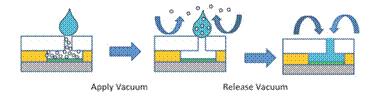

Figure 2. The prefabricated capillary that is used to fill solar cell with.

The solar cell was assembled by thermally adhering Surlyn tape (with a hole punched) at ~110 °C onto the p-‐doped silicon using a hot plate for approximately 10 min. A PSI solution was then vacuum deposited onto the p-‐doped silicon using the hole-‐punched Surlyn tape as a mask. A transparent counter electrode, either fluorine-‐doped tin oxide (FTO) on glass or an optically thin layer of gold on glass, was then adhered to the adhesive side of the Surlyn tape. The counter electrode was machined to have a small hole so that a vacuum-‐assisted capillary effect could be employed to fill the vacant space between theelectrodes with an electrochemical mediator solution. The vacuum-‐assisted capillary effect used to fill the cells begins by putting a drop of mediator solution in the hole in the counter electrode; then, vacuum is pulled to evacuate the air in the hole. After vacuum is released, the mediator fills the hole, as shown schematically in Figure 2.

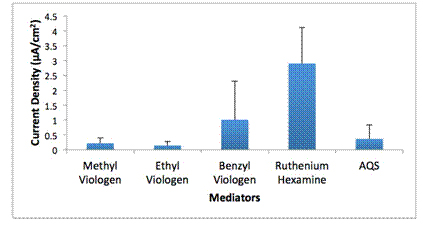

Figure 3. Effect of mediator selection at 2 nM on unetched

Optimization Studies

Mediator. A solution of each mediator (2 mM) with 100 mM of aqueous KCl (electrolyte) was used to test the photocurrent upon exposure to red light of unetched silicon with a single layer of PSI under dark and light environments. The photocurrent densities provided in Figure 3 refer to the short circuit current, the current required to negate the effect of the photovoltage. In the mediator tests, ruthenium hexamine (RuHex) consistently outperformed the remaining soluble mediators. Further, in terms of OSHA standards, potential health effects, and ecological effects, RuHex uniformly ranks as far safer than methyl viologen, which is the mediator we have used in a published paper. Given this trend, RuHex was chosen as the mediator to incorporate into our final solar cell design.

Counter Electrode.We determined in the cell fabrication methods that we did not

want to use indium tin oxide (ITO) on polyethylene terephthalate (PET), due to its poor conductivity and flexible nature, and that we desired a more robust counter electrode. The two best options for counter electrodes were FTO and an optically thin coating of gold on glass (5 nm gold; 2 nm chromium-‐allows adhesion of gold to substrate). Solar cells were constructed using unetched p-‐doped silicon and the two different counter electrodes. Photocurrents that were achieved by the evaporated gold on glass were 30% higher than those obtained with the FTO counter electrodes, which could be due to the thinner glass (for gold on glass) which impedes light less and the improved conductivity of this electrode. From this study the transparent counter electrode that was selected for the final cell was evaporated gold on glass.

Etched or Unetched Silicon. Working with unetched silicon offers some key

advantages. One of the reasons for working with unetched silicon is that the surface of etched silicon eventually re-‐oxidizes, especially rapidly in aqueous environments. Thus, if an effective mediator for unetched silicon can be found, it would increase the long-‐term effectiveness of the solar cell. Also, using unetched silicon increases the ease of production for the solar cells because it avoids the use of harmful chemicals (hydrofluoric acid) that are required to etch the surface. In a direct comparison, the photocurrent from unetched silicon was 45% of that measured for etched silicon right after sample preparation. Considering the rapid decay in performance of etched silicon with time, this level of performance was deemed acceptable.

Plant Source. Our team was published in the cover ofIndustrial Biotechnology(D. Gunther, G. LeBlanc, D. Cliffel, and G. K. Jennings,Ind. Biotech., 9, Feb. 2013, pp. 37-‐41) for investigating the rapidly growing kudzu vine as a source for PSI in biohybrid solar cells. We found that PSI can be extracted from kudzu and exhibits similar biohybrid performance to PSI from spinach. However, the kudzu PSI is collected at a lower concentration, thus requiring additional processing steps to fabricate the PSI film as compared to the spinach PSI film. EPA support was acknowledged.

Taking the optimization data into account, a final solar cell was constructed:

i) Unetched p-‐doped silicon as the working electrode

ii) 100 mM ruthenium hexamine as the mediator (in 100 mM KCl as electrolyte)

iii) 2 layers of spinach PSI (rinsed between the depositions with 100 mM KCl) to achieve a thickness of 1 – 1.5 µm

iv) 5 nm evaporated gold on glass as the counter electrode

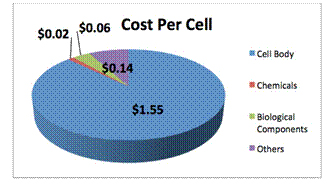

Figure 4. A pie diagram illustrating breakdown of a single

solar cell with an 3.87 2m

This optimized cell generated an estimated 4 mW/m2of power. Further, we showed that the photocurrent was not diffusion-‐

limited due to the ultrathin Surlyn® spacer that places the counter electrode within several micrometers of the PSI film. The overall performance is an order-‐of-‐magnitude improvement over the design by the 2011-‐12 Phase I team. However, the cost corresponds to $1 per 𝜇W of electricity produced by the cell at this stage of development. The cost breakdown of the cell’s components is shown in Figure 4.

Future Activities:

Plan for 2013-‐14. The 2013-‐14 design team is currently working to improve performance of these biohybrid systems. Potential methods that the chemical engineering students on the team are investigating include the use of thin conductive coatings to protect the etched silicon surface from oxidation and the use of more effective mediators that are environmentally friendly and can be used at high concentrations to elevate photocurrents. Mechanical engineering students on the design team are investigating electrodes that allow more light to enter the cell, and reducing the cost of the cell body while achieving a leak-proof and mechanically robust design. Further, as a longer-‐term goal in which more research is needed, designing a solid-‐state biohybrid solar cell should enable improved cell stability as oxygen and water would be excluded from the fabrication.

Journal Articles:

No journal articles submitted with this report: View all 4 publications for this projectSupplemental Keywords:

photosynthesis, photoelectrochemical, siliconProgress and Final Reports:

Original AbstractP3 Phase I:

Don’t Eat Your Spinach: Nature Inspired Biohybrid Solar Cells | Final ReportThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.