Grantee Research Project Results

Final Report: Development of Real-Time Flare Combustion Efficiency Monitor

EPA Contract Number: EPD13024Title: Development of Real-Time Flare Combustion Efficiency Monitor

Investigators: Zeng, Yousheng

Small Business: Providence Photonics, LLC

EPA Contact: Richards, April

Phase: I

Project Period: May 15, 2013 through November 14, 2013

Project Amount: $79,854

RFA: Small Business Innovation Research (SBIR) - Phase I (2013) RFA Text | Recipients Lists

Research Category: Small Business Innovation Research (SBIR) , SBIR - Air and Climate

Description:

There are thousands of flares operating at petroleum refineries, chemical plants and other industrial facilities in the United States, and many more in other countries. Flares are used as a safety and emission control device to combust process vent gases that are otherwise difficult to control. Because flares operate in open air, currently there is no good method to measure or monitor the combustion efficiency (CE) or destruction and removal efficiency (DRE) of a flare. In the state of Texas alone, there were 1,130 flares in 2006 that emitted 13,078 tons per year of volatile organic compounds (VOC), a portion of which was air toxics, based on an assumed DRE of 98%1. Research has shown that the assumed 98% CE or DRE is not reliable and that actual VOC emissions could be drastically different from estimates using current estimation method.

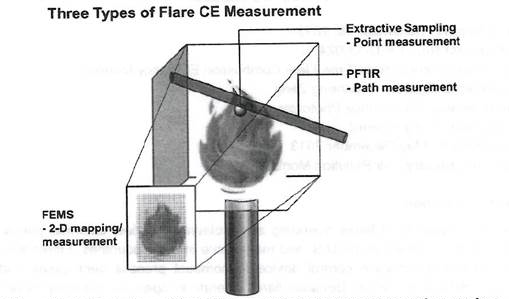

Figure ES-1. Illustration of Three Types of Flare CE Measurement Approaches.

Summary/Accomplishments (Outputs/Outcomes):

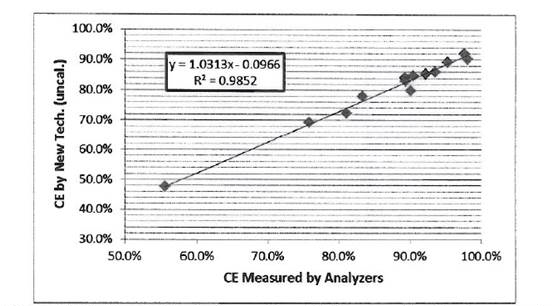

Figure ES-2. Correlation between True CE Measured by Analyzers and CE Determined by the

New Method without Callibration.

Conclusions:

This Phase I study has validated the proposed real-time flare combustion efficiency monitoring technology. The technology is capable of directly, remotely and continuously monitoring flare CE and temperature. The bench-scale test has demonstrated both the technical feasibility and the superiority of this technology over existing flare measurement methods. The commercial product derived from this technology will be an industrial-grade monitoring device that can monitor performance of one or more flares in real-time and enable operators to adjust and optimize flare operating conditions. It also could be connected to a control system to automatically optimize flare operations.

References:

Supplemental Keywords:

air pollution, flares, flare efficiency monitoring, air toxics emissions, volatile organic compound (VOC), imagerSBIR Phase II:

Development of a Real-Time Flare Combustion Efficiency Monitor | Final ReportThe perspectives, information and conclusions conveyed in research project abstracts, progress reports, final reports, journal abstracts and journal publications convey the viewpoints of the principal investigator and may not represent the views and policies of ORD and EPA. Conclusions drawn by the principal investigators have not been reviewed by the Agency.